Description

The SH series diesel engine is popular on the coach market due to its small volume and strong power, low fuel consumption and a large torque at low speeds. We offer two models at 4.3 and 6.5L respectively, with the power ranging from 120 to 280Ps. It is an ideal power choice for a new generation of environmentally friendly coaches and new energy coaches, meeting Tier IV, V emission standards.

The SH series engine was jointly designed with the UK company RICARDO by referring to international technology found in advanced engine and using the GPDP development process. It is a new generation engine with four-valves and a light weight, manufactured under SAIC MOTOR manufacturing standards. The reliability and economy are of first class levels.

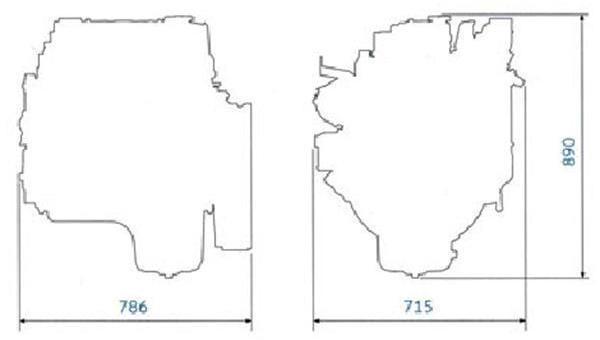

Outline dimensional drawing

4SH

7SH

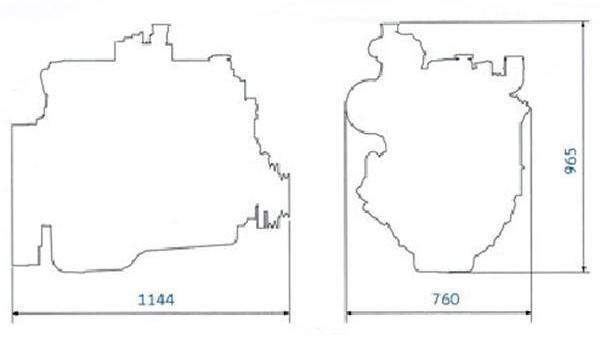

Technical parameters

| Diesel Engine | Engine Model | Displacement (L) | Aspiration | Rated Power | Peak Torque | Emissions Level | |||

| kW | ps | r/min | N.m | r/min | |||||

| 4SH | 4SH120 | 4.3 | TA | 88 | 120 | 2300 | 400 | 1200~1600 | China IV, China V |

| 4SH | 4SH140 | 4.3 | TA | 105 | 143 | 2300 | 550 | 1200~1600 | China IV, China V |

| 4SH | 4SH140 | 4.3 | TA | 105 | 143 | 2500 | 420 | 1200~1600 | China IV |

| 4SH | 4SH160 | 4.3 | TA | 118 | 160 | 2500 | 500 | 1200~1600 | China IV |

| 4SH | 4SH170 | 4.3 | TA | 125 | 170 | 2300 | 600 | 1200~1600 | China IV, China V |

| 4SH | 4SH180 | 4.3 | TA | 132 | 180 | 2300 | 660 | 1200~1600 | China IV, China V |

| 7SH | 7SH180 | 6.5 | TA | 132 | 180 | 2300 | 660 | 1200~1600 | China V |

| 7SH | 7SH200 | 6.5 | TA | 147 | 200 | 2300 | 750 | 1200~1600 | China IV |

| 7SH | 7SH215 | 6.5 | TA | 158 | 215 | 2200 | 900 | 1200~1600 | China IV, China V |

| 7SH | 7SH220 | 6.5 | TA | 162 | 220 | 2500 | 800 | 1200~1600 | China IV |

| 7SH | 7SH230 | 6.5 | TA | 170 | 231 | 2300 | 900 | 1200~1600 | China IV, China V |

| 7SH | 7SH245 | 6.5 | TA | 180 | 245 | 2300 | 960 | 1200~1600 | China IV, China V |

| 7SH | 7SH260 | 6.5 | TA | 192 | 261 | 2300 | 1000 | 1200~1600 | China IV, China V |

Features

| SH Series | Technical advantages and features | Customer value |

| Fuel system | The HP3 third generation electronic control system is customized by Denso for use in the SH series, and features an injection pressure of 1800bar. It uses a ceramic coated, 7-hole fuel injector from Denso. The precisely controlled multiple injection and vertically and centrally arranged fuel injector result in uniform atomization and full combustion. This engine meets Tier IV, V emission standards. | It has a high reliability and long service life. Its fuel consumption is 10% lower than the similar products. |

| Gas system | The electronically controlled ECU, sensor, electronic throttle, sparking coil and other key components are all from internationally known brands. According to different applicable markets, the 4SHT uses a BOSCH control system and the 7SHT uses a WOODWARD control system. It meets Tier V emission standards. | This system is proven and reliable with an excellent economy. |

| Aspiration method | With four-valves per cylinder, the turbocharger (optional for two-stage supercharging) and intercooler are paired in order to achieve a higher air intake efficiency and reach the optimized match between power performance and economy. The optimized designs of the combustion chamber and swirl ratio airway improve the combustion efficiency. With a high power density and excellent transient load response, the maximum torque reserve is up to 36% and the maximum torque is up to 1160N.m, which is 20% higher than other similar products. | With a strong power, there is a strong adaptability to different working conditions. With a low fuel consumption, the operation cost is low. |

| Design features | According to international first-class engine standards and using the GPDP development process, this engine series was designed together with the UK company HRICARDO following an allowable peak pressure of 180bar. This engine uses a rear gear chamber, high strength alloy cylinder block, closed-loop frame structure, main bearing diaphragm plate and other designs to reduce vibration and noise. The size is 77-140mm shorter than similar products. | The advanced nature and reliability are ensured. The noise is reduced by 3dB to ensure comfortable driving. With a convenient and flexible arrangement, the heat dissipation performance is outstanding. |

| Reliability features | It uses a high strength frame cylinder block structure, modular design and integral engine oil cooler, pump and oil pump. During the research and development stages, we conducted testing of over 2,000h for frame reliability and durability, and a road test of more than 1 million km to test operation in plateaus and extremely hot/cold environments. Automatic production and assembly lines for the H series are customized by HELLER, KUKA, US0N and other international first-class equipment manufacturers, and are controlled by an MES system. Referring to the SPS system guarantee from German Volkswagen manufacturing standards, the product features an excellent consistency and high reliability. | The maintenance cost is reduced, with an excellent plateau adaptability and little to no downtime. |

| Matching adaptability | With an optional displacement of 4.3L and 6.5L, and optional engine fuel of diesel or natural gas, the operating power ranges from 60 to 162kW. Without an auxiliary air intake heating device, the cold starting temperature is -15℃. The engine and assembly are paired for matching optimization and customization based on the assembly configuration and actual operating conditions. There are various configurations for the flywheel, flywheel house, engine, air compressor, steering pump and other peripheral parts for customers to choose from. There are also various structures and types for the PT0 and oil pan. | The fuel has a diverse selection with a wide power range. It has an excellent environmental adaptability. The power performance and economy are simultaneously optimized. It satisfies various application requirements. |

| Maintenance | A CAN buss layout achieves an intelligent, real-time diagnosis. With a cracking connecting rod, the accessibility for maintenance is easy. The electronically controlled system provides an intelligent real-time diagnosis. The average overhaul interval is over 15000h, which is more than 50% longer than other similar products. | The maintenance is convenient with very little downtime. |